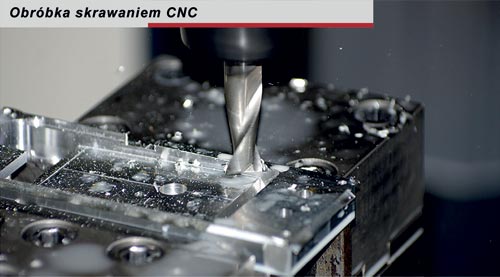

Our company specializes in the implementation of orders in the field of machining metals and plastics by turning and milling on a lathe and milling machine.

We roll and mill every material.

Maximum dimensions of milling: 6000 mm x 2500 mm x 1200 mm

Maximum dimensions of turning: Ø 2000 mm L 1000

We provide services in the field of machining such as:

- CNC turning, also large-size on a CNC lathe

- CNC milling including 5-axis, also HSC

- Milling grinding,

- electrical discharge machining (EDM, WEDM)

- bending of rods, CNC pipes

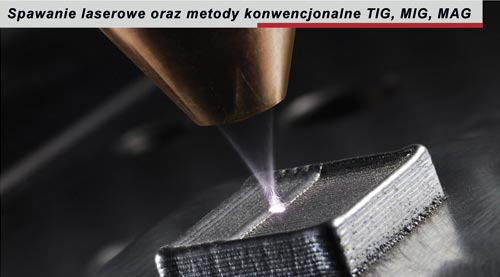

- MIG / MAG / TIG welding

- laser welding

- cutting with an abrasive stream of water

- 5-axis laser cutting (flat, pressed, hydroformed sheets, straight, bent tubes, sections etc.)

We cut steel, aluminum, copper, brass, plastics, stone, etc. Maximum thickness 200 mm.

This method is unique. It performs precise cutting of details without further processing.

The advantage of the water cutting method is the lack of unfavorable influence of high temperatures on the cut out elements as it happens, eg when firing details with plasma. Other advantages are high accuracy, ensuring no need for additional processing.

Some non-standard orders, requiring constant repeatability, are only suitable for laser cutting. This technology is much cheaper, more precise and faster than the methods previously used.

Laser welding opens up new possibilities for precise and demanding welding tasks. Thanks to this service, our clients’ processes become simpler, faster and safer.

The Maltex company offers the possibility of bending sheet metal using the latest press brake. This process is fast, efficient and at the same time affordable. Computer control ensures its maximum precision and 100% repeatability of effects.

Thanks to the excellent technological base, we are able to implement even the most demanding orders. Our prices are affordable thanks to the use of efficient bending processes that allow us to avoid mistakes and materials damage. We cut all kinds of steel up to a maximum width of 3 meters.

- Bending of pipes and CNC profiles

- The maximum diameter of the pipe is 80 mm

- The maximum diameter of the rod is 40 mm

PA12 polyamides are used for printing using this method. Items are created by applying successive layers of powdered material and their selective sintering using a laser beam.

This technology does not need supporting structures. The unheated powder itself is a suitable support. Thanks to this, it is possible to create even the most complex shapes and spatial structures with a small wall thickness, at the level of a millimeter.